This is a small production formula. If you want to make at home you must convert the ingredients to 1/3 of the formula. [# = lb]

Sour :

- 4# Cold water

- 2 oz. Yeast

- 2 oz. Malt

- 4# High Gluten Flour

- 2# Rye Meal or Pumpernickel

Procedure:

Mix in a 20 qt bowl with a hook, and let set out, covered with plastic, until next day.

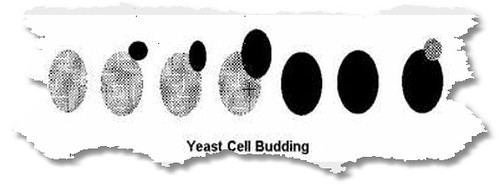

Your sour will resemble this :

|

| AP Sour After Overnight Fermentation. |

Dough:

- 8 # Water (cool )

- 12oz. Honey

- 4oz. Instant Yeast

- 10# Hi Gluten Flour

- 3# Rye Meal

- 2oz. Malt

- 8oz. Salt

Place water honey & sour into a 40 qt bowl.

|

| Honey, water & AP Sour in mixer bowl. |

|

| Mixing of the AP dough. |

Add the rest of your ingredients - mixing with a hook, until smooth. Mixing time is approximately 4 minutes beyond clean up stage. Dough temp should be 78°F .

|

| Blocking AP Finished Dough. |

Remove the dough from the bowl, lightly flour the bench [

work space] and block the dough. Divide dough using a hot dog cut [

easier to scale]. Scale to 1# 3oz., round immediately.

|

| Scaling AP Dough to 1# 3oz. |

|

| Rounding AP Dough. |

|

| AP rounds on Board. |

Rounds are then put on boards. Let relax 5 minutes covered.

|

| Egg washing re-rounded AP rounds. |

Re-round, lay on board lined with proofing cloth, tuck proofing cloth between rows [

to prevent sticking] and egg wash. Proof for 25 minutes.

|

| Making Beehive cut in proofed AP rounds. |

Once proofed, put 6 on a cornmeal prepped peeler, using a a sharp blade, make a beehive cut/swirl cut - starting from bottom, side cut upwards in a curving motion & meet 1 inch from center . Continue until you have four equal cuts, which offset each other.

|

| Loading cut AP rounds into oven w/ peeler. |

BAKE AT 450° F. Use "thump" test to check for correct bake-off.

|

| Baked AP rounds. |

Has a fine crumb, light. Not dense at all, and not much for sharp rye flavor - more nutty. I don't care for rye, yet I loved this bread. Most people when they think of rye , they think of the hors 'd ouvres sized crouton - hard rye mini loaves you add cheese to. This bread is not at all like that. It is similar to a whole wheat.

Traditional rye is very dense, and calls for mainly rye flour. Rye flour doesn't have gluten. Hence the dense bread. It is more popular on the East coast. You won't find too much Rye bread on the West coast.

I find it funny that we as North Westeners love artisan breads and our organic, healthy lifesyles, yet can't find room on our palate to appreciate rye...

as you see here the outside has quite the texture. When you take these loaves out of the oven they literally sing -- the outer crust is sizzling and screaming. Bread songs are magic for a baker.

as you see here the outside has quite the texture. When you take these loaves out of the oven they literally sing -- the outer crust is sizzling and screaming. Bread songs are magic for a baker.